Microarchitecture

Independent project

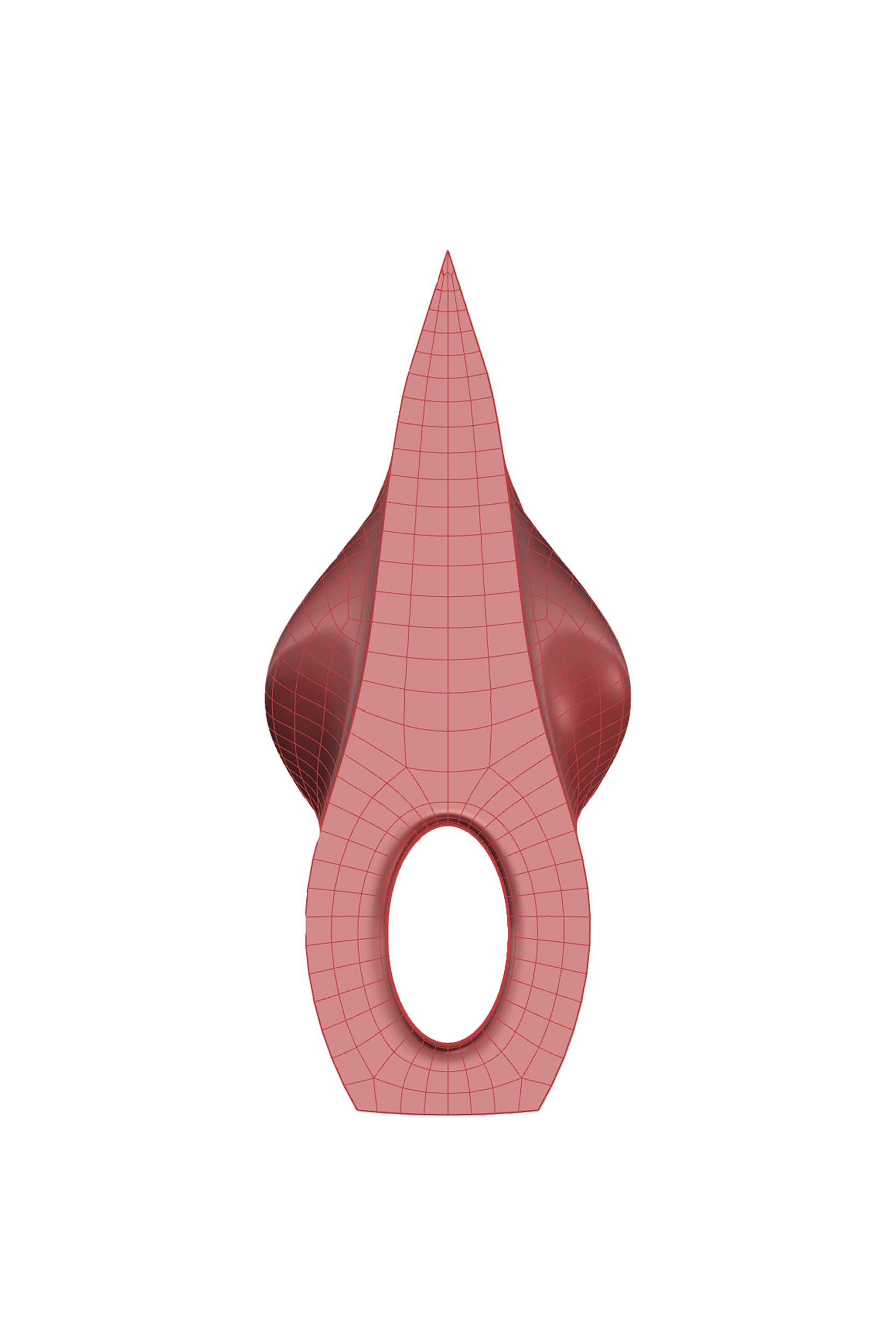

Tool design concept.

Concept development

Sketching, CAD in Rhinoceros, prototyping in plaster,

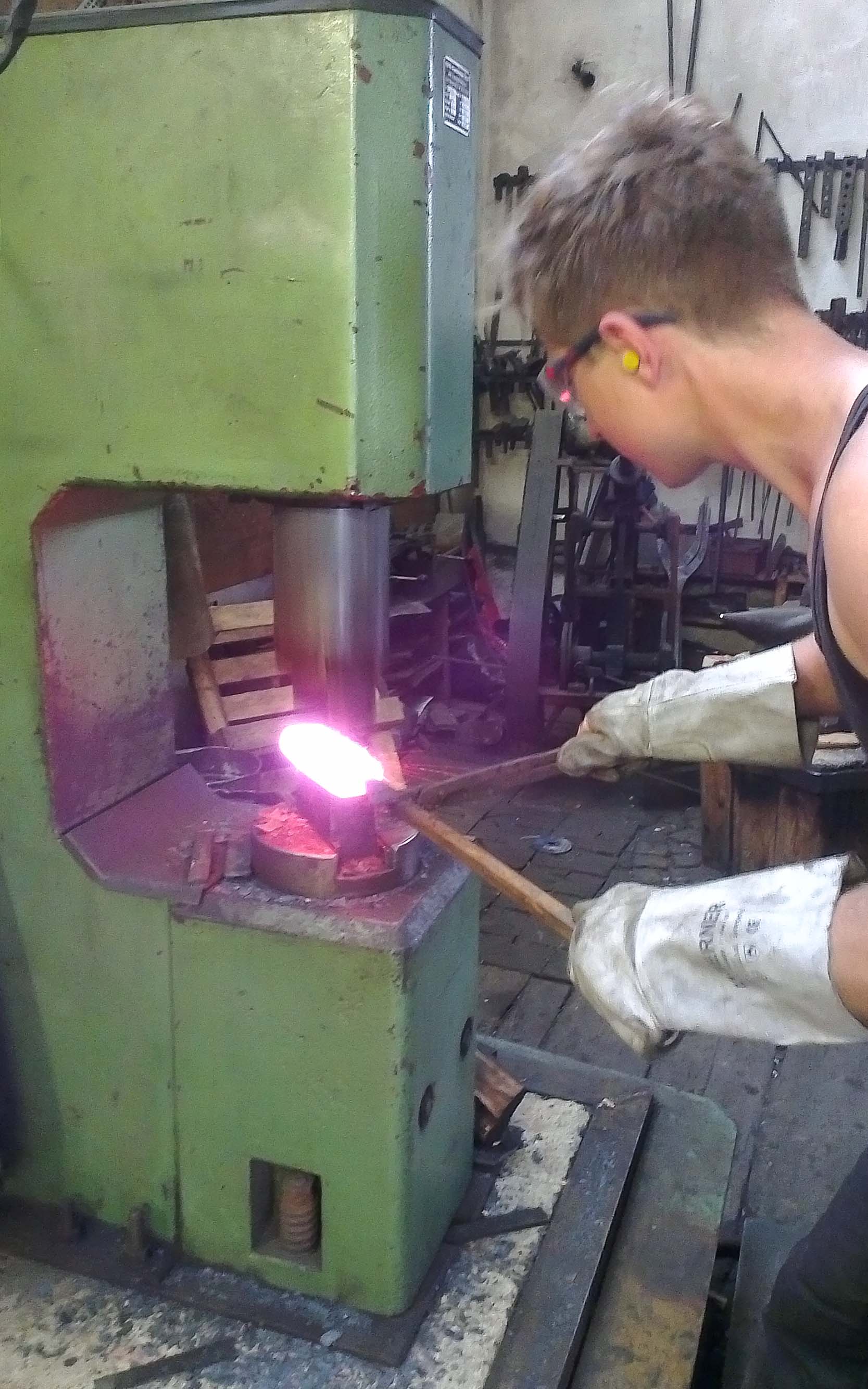

Ergonomic studies, Free from forging.

Realisation

Forged and hardened carbon steel, Ash.

130 x 45 x 90mm

300g

The development of a hatchet was done by drawing, shaping and modeling processes involving plastolin, paper and plaster.

In a free-forging process the hatchet is plastically shaped. This method contrasts the subtractive form-finding process in plaster. In combination with the handle made from ash wood, the hatchet provides an ergonomic and functional unit.

Two advantages are obtained from the crimped and arched cheek, that also inspired the works title Microarchitecture: it provides a protective handle for the hand to cut off small chips when used like a carving knife and generates stronger splitting force.

In a free-forging process the hatchet is plastically shaped. This method contrasts the subtractive form-finding process in plaster. In combination with the handle made from ash wood, the hatchet provides an ergonomic and functional unit.

Two advantages are obtained from the crimped and arched cheek, that also inspired the works title Microarchitecture: it provides a protective handle for the hand to cut off small chips when used like a carving knife and generates stronger splitting force.